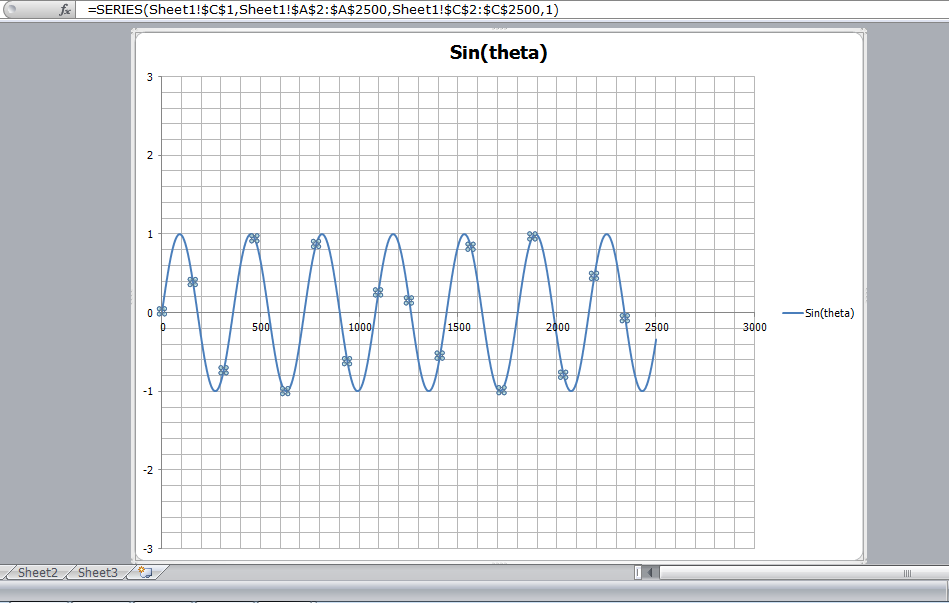

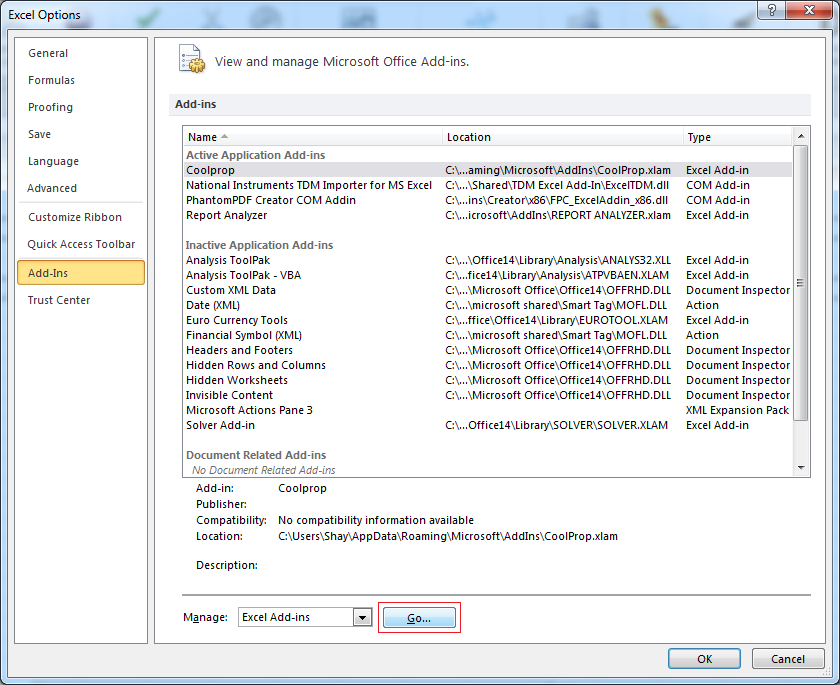

After searching a lot for the solution of this problem, I want to introduce it. For charts, MS Excel does not has a native function to get the source range address for series collection, but we can -with a trick- get some useful information about the source range using string processing.

The following two pictures show the layout of series collection formula. I noticed that sometimes I get the first layout and sometimes I get the other one (I don't know exactly when I get each one). The difference between them is just the quotation marks of sheet name. The series collection formula has four data:

(1) Data series name: represented by address or string

(2) Independent variable (x-axis) values: represented by address or defined name

(3) Dependent variable values (y-axis) represented by address or defined name

(4) Index of data series (read only value)

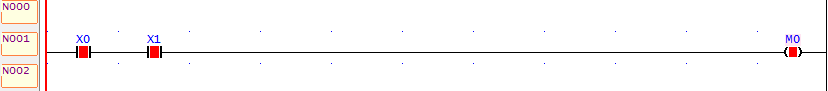

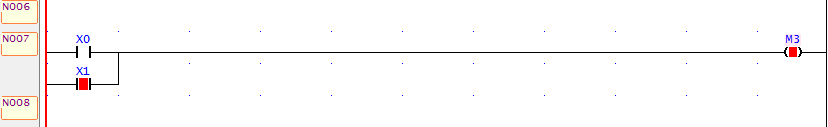

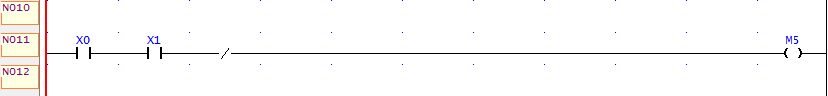

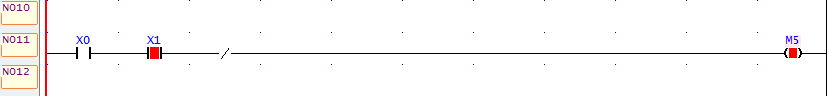

The first layout (with quotation marks):

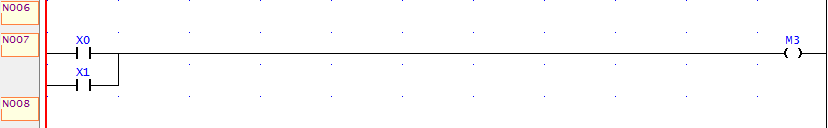

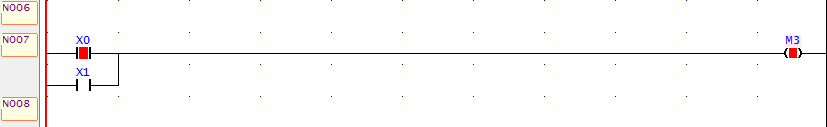

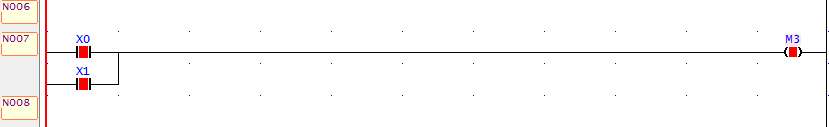

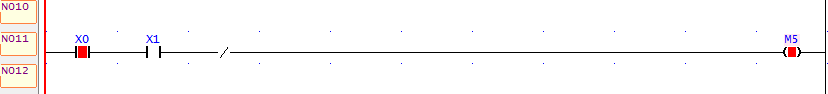

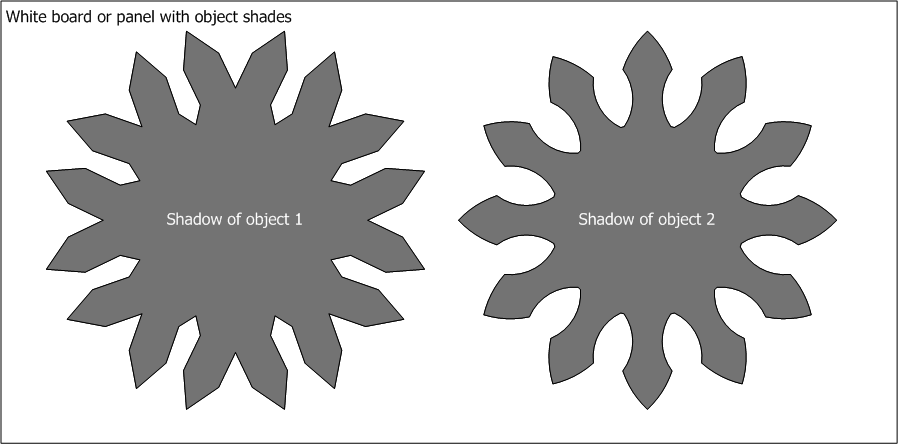

The second layout (without quotation marks):

The following two pictures show the layout of series collection formula. I noticed that sometimes I get the first layout and sometimes I get the other one (I don't know exactly when I get each one). The difference between them is just the quotation marks of sheet name. The series collection formula has four data:

(1) Data series name: represented by address or string

(2) Independent variable (x-axis) values: represented by address or defined name

(3) Dependent variable values (y-axis) represented by address or defined name

(4) Index of data series (read only value)

The first layout (with quotation marks):

The second layout (without quotation marks):

The following code demonstrates how to get source sheet name for the second layout (Excel 2007)

Sub GetSeriesCollectionData()

' Get the

formula of the first data series

SeriesCollectionFormula =

Charts("Chart1").SeriesCollection(1).Formula

' Some string

processing...

StartPos = InStr(SeriesCollectionFormula,

"(") 'Index of first "(" found in the string

EndPos = InStr(SeriesCollectionFormula,

"!") 'Index of first "!" found in the string

' Extracting

the name of source worksheet using Mid function

SourceWorkSheet = Mid(SeriesCollectionFormula, StartPos + 1,

EndPos - StartPos - 1)

'Display the

source work sheet in a message

MsgBox ("The name of source work sheet of

this chart is : " + SourceWorkSheet)

End Sub

|

.png)

.png)